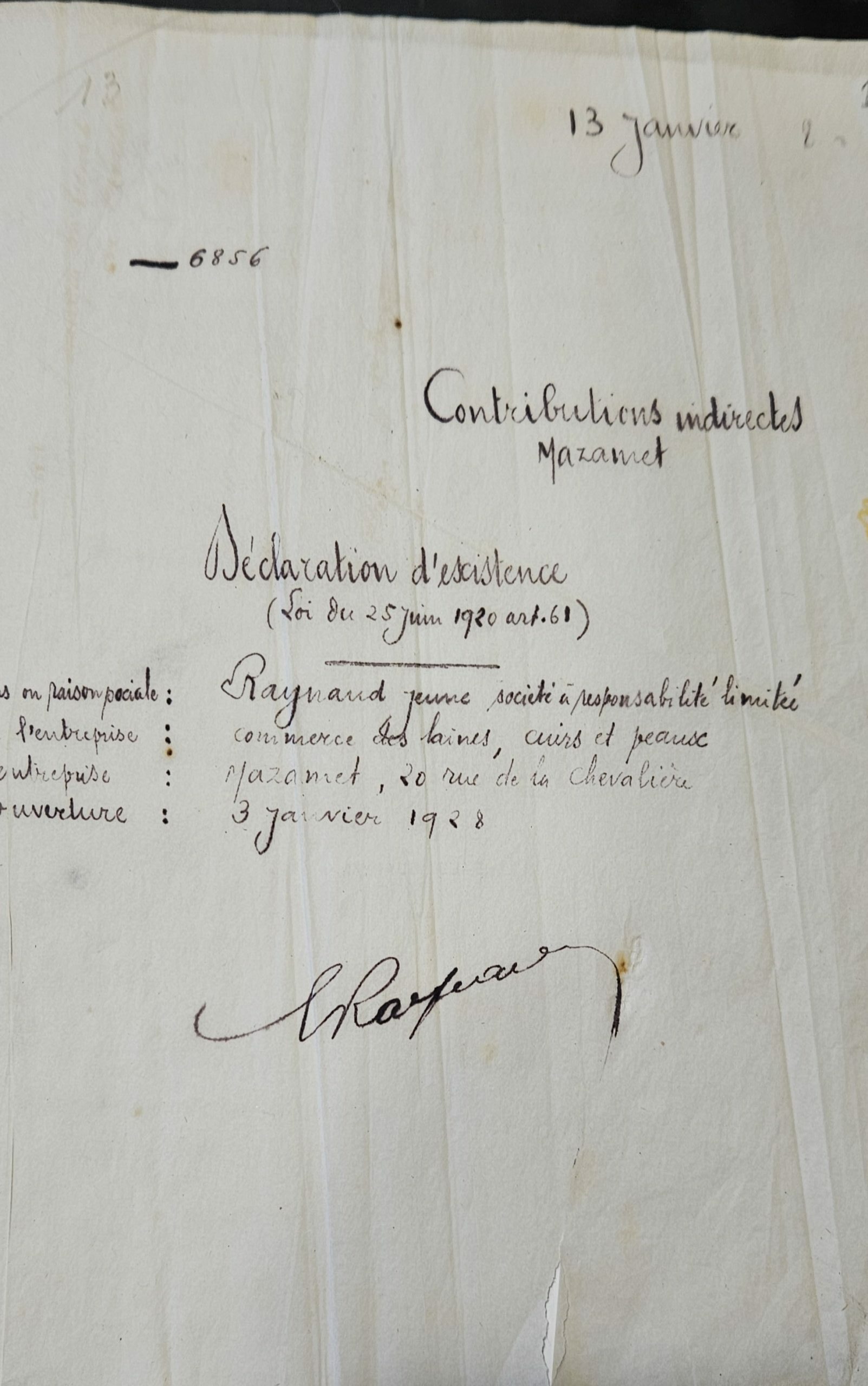

François Raynaud took over the company in 1948, and had sheepskins made to order in the Longchamp factory, which was founded in 1892, in Lacabarède.

Incorporated into the company in 1973, the Longchamp factory completed its activities in the 1980s, producing pickled skins, then “basanes” (vegetable tanning) and finally finished leathers for clothing or leather goods.

Up to 4,000 sheep skins, mainly from New Zealand, are processed every day on the site.

The company is now managed by the third generation with Olivier Raynaud, who joined in 1988.

A diversified and expanded activity over the years

The 1980s and 1990s saw the development of sales of finished leathers abroad (South Korea, United States, Canada, Japan, etc.). In the same time classic insole leathers remained one of the main items produced on site.

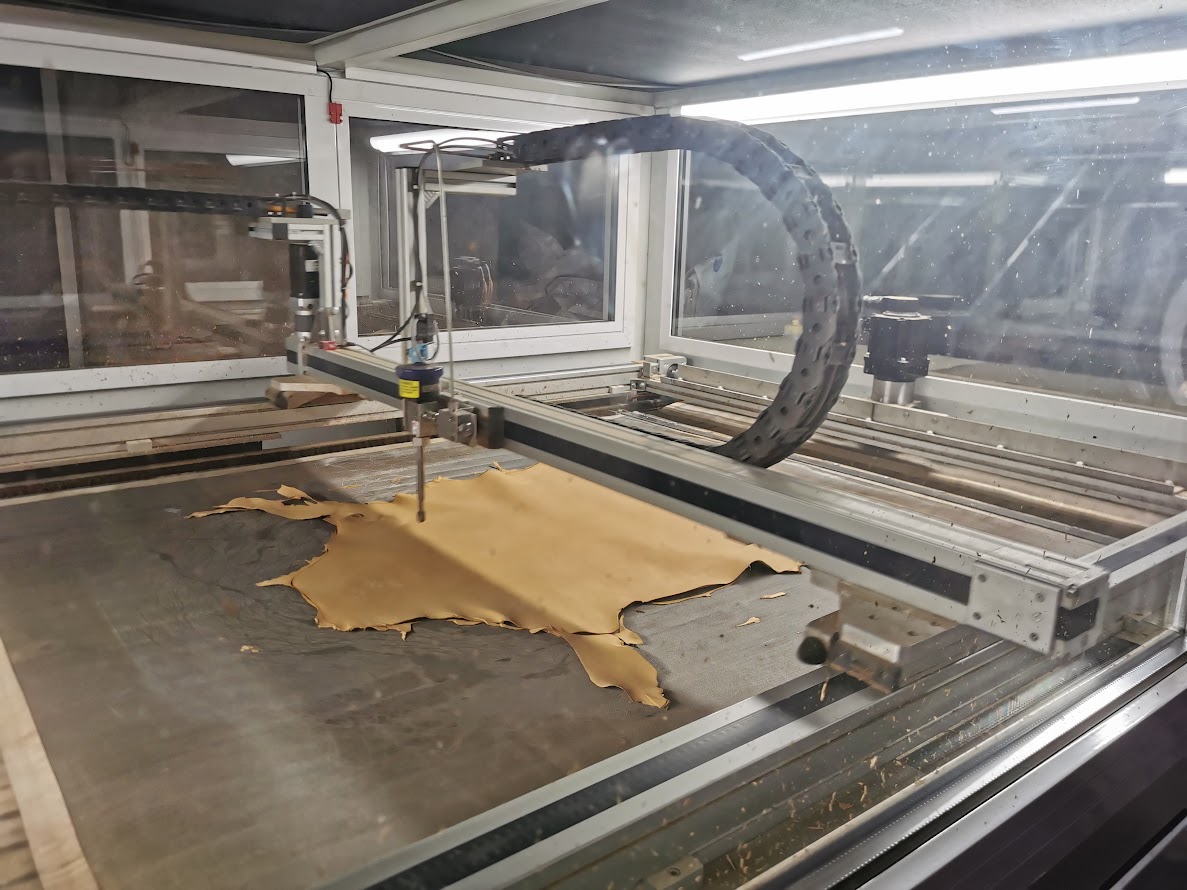

The Longchamp (Rouairoux) production site covering more than 4,000 m2 can now meet the growing demand for vegetable-tanned products.

In 1985 the Raynaud Jeune company built the first wastewater treatment plant in the Mazamet wool and tannery basin.

This one is supplemented by a second biological unit commissioned in 2013.

Today Raynaud Jeune, while relying on its solid foundations as a major supplier for insole manufacturers, is relaunching a new range of innovative products for the high-end clothing, footwear and leather goods industries.

Its team of 30 employees, recently largely rejuvenated, allows Raynaud Jeune to meet all the new challenges that arise today.

Raynaud Jeune is present all over the world and at the main trade fairs.

Raynaud Jeune is today the largest lamb tannery in Mazamet and one of the market leaders in vegetable tanned lamb skins

The involvement of Raynaud Jeune and his know-how are recognized throughout the world.

In a vision of the future and sustainability, the company is pursuing an ambitious investment and renovation program, both at the environmental level and at the production level.

His efforts were rewarded by the obtention of the LWG (Leather working group) certification, with the Silver Level.